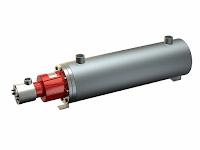

Tubular Heater

Tubular Heater Considered as the most useful of all electric heating elements, tube heating elements, and materials that can be used for all temperatures, whether for solid heating, liquids, or gases, water heater elemental structures are used in various forms, offering the advantages of heat distribution and simple installation in industrial applications. Heating elements derived from the metal tube sheath of the material are selected to satisfy a particular application. This sheath, clean the helix of chrome resistance wire, centered and tightly compacted with electrical insulators and heat transfer media from magnesium oxide (MgO). This provides a spiral resistance that can vary in the concentration of heat and long section. Almost any shape or size can be made upon demand. Usually, the used materials are steel, stainless steel, Incoloy, Inconel or titanium. Tubular elements are often referred as the basic elements of heating. Tubular Heater Spiral Tubula...